Perma-Liner Industries, Inc. supplies its Perma-Lateral™ installers only certified third party tested and approved lining materials. Our patented scrim reinforced liner and 2-part formulated epoxy resin ensures you're is in accordance with city and state specifications. ASTM F1216 specifications require a minimum life expectancy of 50 years…our Perma-Lateral™ certified third party testing provides life expectancy 70 years plus!

Only Perma-Liner™ provides user friendly equipment, patented liner material with an ambient cure resin.

Only Perma-Liner™ provides user friendly equipment, patented liner material with an ambient cure resin.

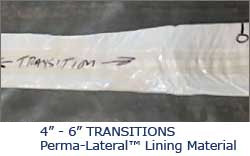

Perma-Lateral™ inversion liner materials consist of two layers of flexible needled felt and one layer of our scrim reinforcement, capable of carrying resin, withstanding installation pressures and curing temperatures. The material is designed to stretch in order to fit irregular pipe sections and negotiate 22's, 45's and sweeping 90° bends in all types of pipe materials.

The outside layer of the tube is coated with a 2 mil thick Polyvinyl Chloride finish. The tube is fabricated to a size that when installed will expand and tightly fit the internal circumference and length of the original conduit.

Perma-Lateral™ thermal bonding process insures the best seam in the industry. Our seam is subject to a consistent dwell time, pressure and temperature. The automated process insures a stronger seam and more pipe flexibility. Competition uses manual flame bonding sealing techniques, which are subject to human error. Dwell time, temperature, pressure and continuous seaming are prone to failures when subject to potential human error. Manual flame bonding also adds stiffness, which reduces flexibility and creates inversion resistance.

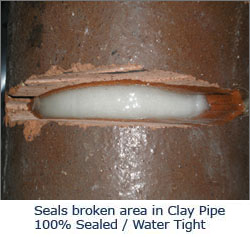

The outside of the liner is sealed to the inside of the old pipe.

Stormwater can not flow between the old pipe and the new pipe liner.